Bob Beaumont’s Seabring-Vanguard CitiCar

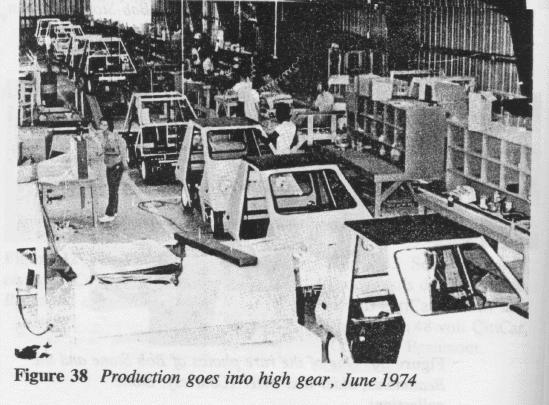

There have been many attempts at making EVs available to the public over the years. The best known attempt in recent years was made by Bob Beaumont in the 1970s as a response to the “energy crisis,” (actually an artificial oil crisis caused by an embargo from OPEC and not an energy crisis). He brought the world the Seabring-Vanguard CitiCar, the diminutive cheese wedge shaped electric vehicle for two. It was an idea he got from riding around in an electric golf cart. They were designated street legal and he sold 2,200 before running into financial trouble. For a brief moment in history this electric car company was America’s 6th largest automobile producer. But, congress pushed up bumper crash requirements, and the safety issue became a noted problem with the Seabring-Vanguard product. Congress dropped the bumper requirements after Seabring-Vanguard was gone.

There was an attempt to revive the company for the commuter car market under the name Commutacar. It eventually died because gasoline was cheap again and no one wanted these tiny things for just commuting. This proves that if a car has no appeal other than fuel economy then it will not exist when gas prices are low.

Gary Starr’s Solar Electric Engineering Produced the Destiny 2000

In the 1990s a Gary Starr of Solar Electric Engineering, took his substantial knowledge in making and marketing solar electric trinkets such as solar powered pith helmets, combined it with his personal knowledge of converting automobiles to electricity, and manufactured a series of production/conversion electric cars. The most famous of which was the Destiny 2000, featured in the movies Naked Gun 2 ½ and 33 1/3. He went the route of cherry picking used cars to produce his vehicles. Destiny 2000’s were built from used Pontiac Fieros. These vehicles had rear trunk lids made out of solar panels and had solar panels embedded into a custom made front hood. They also produced conversions of S-10 pickup trucks, VW rabbits and some other cars. They were hoping for money from major automakers to come in the form of credits for not meeting the ZEV mandate in California, however, all the major automakers produced some sort of vehicle to meet the early stages of the mandate. Solar Electric Engineering saw some success in producing the S-10 pickup that they sold largely to utility companies. The fleet sales division did much better than the regular EV division and was spun off as USElectricar.

Bob Beaumont’s Tropica

Bob Beaumont tried again to produce an electric car in Florida. This time it was a very sexy sports car called the Tropica, which was hot, hot, hot looking. Lack of money put him out of business again. The parts were bought by a group of investors involving Don Johnson of Miami Vice and Nash Bridges fame. He renamed the vehicle the Xebra, moved the operations to California and had one painted the color of Jasmine Blight’s eyes and had her drive it around on the show of Nash Bridges. I don’t think the company really produced any vehicles in California, but most likely put together vehicles from the left over parts from its production in Florida.

GM attempted to shake its image as an industry dinosaur involved itself in Solar Racing

and Electric Vehicles

The ZEV (Zero Emission Vehicle) mandate era produced several high quality electric vehicles from the major automakers. The era, however, was started before ZEV legislation by GM itself. GM was caught up in the enthusiasm of the 1st World Solar Challenge of which it was an entrant. The GM solar vehicle won the race and GM contracted with Aeroenvironment, the actual producer of its solar vehicle, to produce a single standard format electric vehicle. Alan Cocconi, now known for AC Propulsion and the Tzero, was the project engineer that produced the car. The vehicle named the Impact had significant increases in range and performance when compared to previous attempts at electric vehicles. It was the hit of the LA Auto Show and its popularity made the otherwise inept GM look like the future of automobiles rather than the dinosaur that it looked like in the 1970s and 80s. GM pledged to make a production vehicle out of the Impact. It did with the EV1 being the end product, producing somewhere around 1800 vehicles. With the LA Auto Show demonstrating that a major automaker could produce a Zero Emission Vehicle (ZEV), the California Air Resource Board (CARB) decided it was time to include a requirement of major automakers to produce ZEVs.

Toyota produced a conversion of its RAV4 mini SUV, which had one just sell on Ebay for over $50,000 dollars. However none of the major manufacturers liked the ZEV mandate. The EV1s were all crushed. Hondas electric vehicles have disappeared. GM has crushed some of its S-10 Electric pickups, but some are still in people’s hands. Ford purchased Pivco and created Th!nk, then closed it and tried to crush all of those vehicles, but opted to send them back where they came from, Norway. They were going to crush the Electric Ranger, but those are being spared.

Toyota Prius is the World’s fastest hybrid with a record speed of 130.794 mph.

The ZEV mandate for the most part has disappeared, but now the major automakers in the United States are feeling the pain for their short sightedness in destroying their innovations. A spike in oil costs and American’s growing concern over the environment and global warming have created an opportunity for Japanese manufactured automobiles again, as they did in the 1970s. In 1993 the Clinton administration created The Partnership for the Next Generation of Vehicles (PNGV). The PNGV was setup to help American auto manufacturers develop family-sized vehicles that could deliver significant fuel savings. Toyota was excluded from participating because it was a Japanese automotive company. Toyota did the typical Japanese business strategic thing. It felt it could not compete with GM in electric cars; GM had come too early and had significant technological advancement and government funding for Toyota to make up the gap. Toyota took the pace position behind GM with a hybrid, preparing to follow until GM stumbled. Toyota did its business leg work and understood that the best alternative vehicle would be a hybrid as an interim step to electric vehicles. Toyota probably expected GM to stumble with poor products and recalls; I don’t think it expected to have the market handed to them by GM bailing out on the future of automobiles. The Clinton administration handed American automakers the keys to the future automobile through PNGV and the US automakers dropped them. Toyota probably believed that the market for hybrids and electric vehicles would go through a transition phase. Sales would slowly increase over time as consumers got used to the idea of hybrids and electric cars and the growing cost of oil creating economic forces that push the consumer in this direction. In the end, I believe, Toyota was surprised by the discovery that the demand for innovative fuel efficient low polluting vehicles was current and very strong. They are still, even today, trying figure out how to meet that demand.

The seemingly unquenchable thirst the consuming public has for innovative fuel efficient low polluting vehicles has now become the entire industries focus. For us EV enthusiasts we have always felt that what the industry was telling us, that there is no demand for such vehicles, was wrong. We now know for certain that there is a real market for EVs. For what ever reasons we now also know with some confidence that that market was clearly artificially suppressed.

So what do we do now going forward? The possibility of a production EV is at a critical stage. Do we allow for a further erosion of jobs in the United States to Japan and else ware, do to the poor response to competitive challenges by the leadership of our industries and our government? I would like to set up an American venture to produce an automaker that will be much more responsive to the wants and likes of its American consumers. We have learned a great deal from the historic ventures into producing EVs. These learned lessons will have to be incorporated into the plans for the new venture.

What we have learned from these ventures successes and failures are:

1. A production-conversion is within our capabilities and probably the easiest and most cost effective way to introduce a product in to the market, however, the used car recycled idea will depress the desirability and value if the vehicle is an outdated model and identifiable as such. If a used car is used to produce mass market EVs it must not look like a used car but must be a clearly distinct vehicle after remanufacture. An advantage of using used cars as the base is that conversions do not have to be recrash tested and go through the regulatory processes that a new car has to go through. However, a new automobile, produced from the ground up to be an EV is probably the best approach into the market.

4. The most popular EVs are functional rather than marginal. What I mean is that the most popular EV and the most capable of holding its value will be a car that has the widest applicable utility. For example, soccer Moms (parents) can use the vehicle to haul kids to school, play and to get groceries. Dad (parents) can put things in the car for fixing up the house. Businesses can use the vehicle for deliveries. Commuters can use the vehicle without feeling that they will be run over by other vehicles. The best example of this has been the Toyota RAV4 EV. When the price of gasoline goes down, which it will (as it has in the past), a RAV4-EV will still be a practical car to a great number of people and businesses. I am thinking of something like a cross between a mid-sized SUV and a mini-van. The shape of Murano seems to be a good example of this and it has good aerodynamics too.

5. The car needs to have appeal other than that of sacrificing for the greater good. Here the RAV-4 wins again. It is an “SUV” (better name is a Cute Ute) so the pull of the open road and the trek back to the wilderness is still possible and that pull has strong visceral appeal to a great many people. In fact it is the main reason that EVs were supplanted as the premier automobile at the turn of the century in early 1900s.

6. An EV must be reliable and quality built. Gary Starr’s cars had little problems that cropped up here and there. Maintenance issues, reliability issues, safety issues, for example my Destiny 2000 has solar panels on it but it leaks water into the trunk and onto the batteries. It’s a solar car that was meant to be kept in a garage!?!?! USElectricar S-10 pick-ups were plagued with little problems and poor workmanship.

7. The EV must have range. They must have ranges at minimum of 350 miles. This is possible using a variety of techniques. For example, series hybridizing, computer controlled cruise controls, larger battery capacity, and more.

8. Competitive pricing. EVs don’t have to match pricing with ICE vehicles. All they need to do is come close, as we have witnessed with the popularity of the Prius, with a several thousand dollar premium.

9. The production EV must be comfortable and familiar. Some of the EVs I have driven are made from very old vehicles. They lack power steering, air conditioning, automatic transmissions. They are not a comfortable ride. Then there are odd buttons with no explanation to what they do or when to push them. Good documentation and a clearly written and helpful owner’s manual would go a long way to making EVs normal.

10. EVs must be serviceable by your local mechanic. Well written repair manuals for mechanics, video training courses and a certification program would make taking your EV to the shop a positive experience rather than a nightmare of rejection.

I have presented some of the things to think about when doing an automobile startup, however, the list of things to consider for true success is considerably longer and too long for this blog. I believe that it is within our capabilities to produce a marketable electric car in the United States. I believe if a fairly large number of us get together, pool our resources and our expertise we could produce a vehicle with greater appeal beyond that produced by the EV enthusiast. I don’t believe that a venture that produces a vehicle from junk parts will ever go beyond selling a hand full of vehicles.

If we were to do the used car route, what I envision is a vehicle plant that has two stages, a disassembly part and a reassembly part. The used vehicle would be chosen for its wide appeal in the market, ease of conversion and the availability of the used vehicles at low prices. The removed parts not useable in the end product EV would be sent to a recycling center, transported to a scrap yard or sold. An example would be like a Dr. Motor Works could take the old motors on consignment. These used parts sales would help the company recoup its cost of acquiring the used vehicles. The remaining parts to be used in the EV would be cleaned and repainted to give them the luster of being new. The vehicle would then go through the reassembly plant. A new distinct front end might be added, an untypical paint color might be chosen in order to distinguish the vehicle from oil powered vehicles; raising its profile and its identity as an EV (or series hybrid). The vehicle would get new carpeting, new interior, new seats, low rolling resistance tires, distinctive wheel design, (maybe sporting the company’s logo).

You get the picture. When the vehicle is marketed it will be a reliable, distinct, functional vehicle for the general public. These vehicles will be sold bundled as part of the purchase with the changes to home electrical needed to handle an EV. This bundle would be an electrician to place a compatible outlet near where the new owner will park the car.

It is possible to make this happen and I believe there are enough people willing to pledge money and other support to make this a reality. What I don’t want to see is this venture to become a place where a group of people pledge their money and their time and then end up squabbling over a million nuances. Believe me, in the production of an automobile, there is abundant opportunity to fight over every tiny part that goes in to it. There must be a firm commitment, by those who invest, in the greater picture, a market viable EV. They must be able to leave the details to those in charge of putting the vehicle together. I know that if there is sufficient capital willing to back this venture that I would be willing to join in with all I have, my time, my expertise and my money.

This Blog was originally published in EVWorld.com.